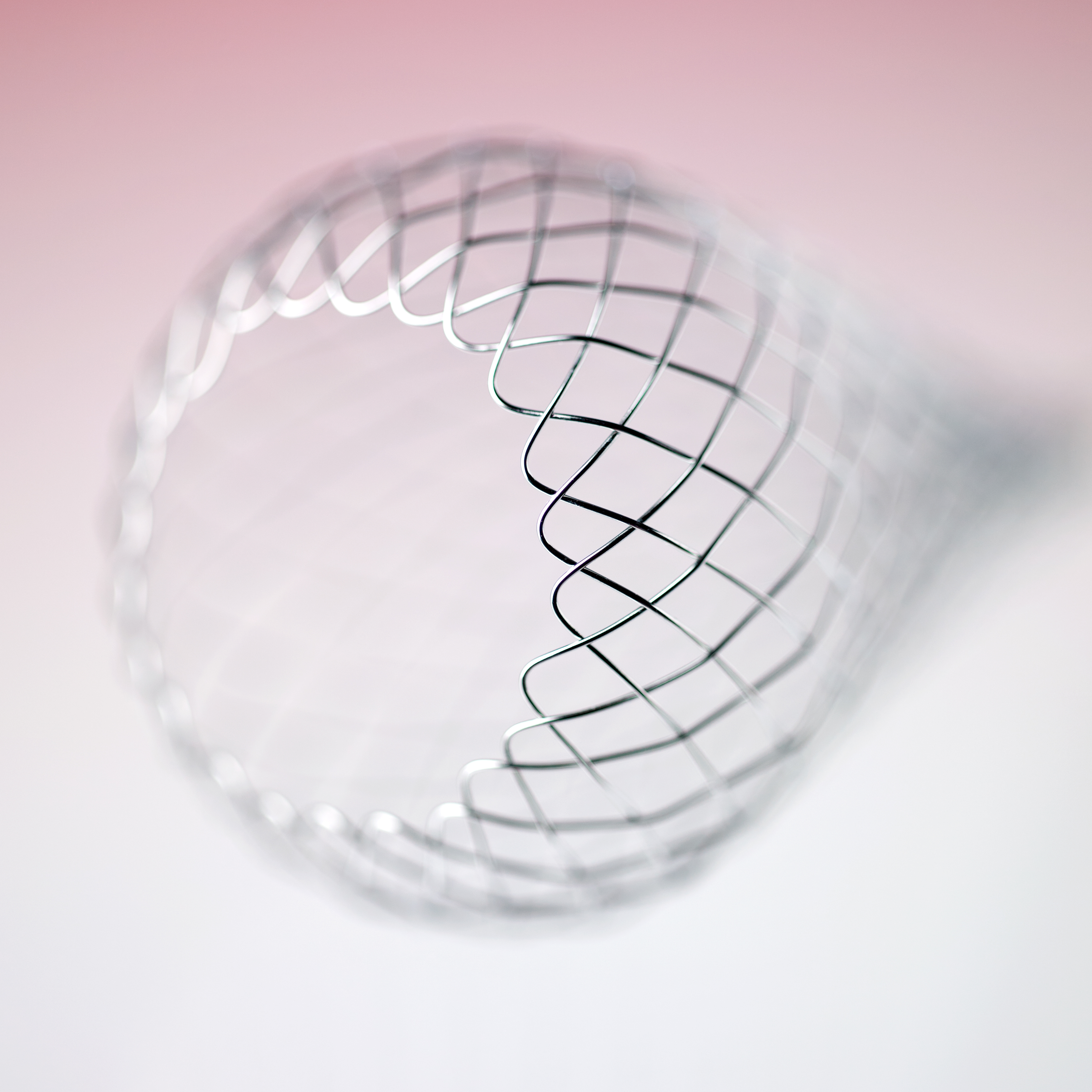

OUR BRAIDING CAPABILITIES ALLOW YOU TO CREATE UNIQUE, COMPLEX, VARIED STRUCTURES.

WIRE TECHNOLOGY.

Our comprehensive selection of wire technologies helps our customers meet the widest array of medical applications. Capabilities include wire processing, forming, braiding and winding, as well as surface treatments that enhance biocompatibility and durability.

We work with you closely to achieve the best possible results, whether that requires conventional wire technology, any of our many patented and proprietary approaches, or something entirely new. Our broad array of wire technology capabilities includes the following:

Wire braiding

Interweaving or twining wire for conventional, flexible, closed-loop and single-wire braiding.

Wire Winding

Fully automated, tension controlled process that produces high-quality and uniform dimensions, characteristics and surface finish in three dimensional structures.

Wire forming

Two- and three-dimensional shapes and unique structures in a wide range of wire diameters and types.

AT-A-GLANCE FACTs

- Braiding materials: Nitinol, cobalt-chrome, DFT composite

- Braiding wire diameter: 15 µm to 400 µm

- Winding wire diameter: 25 µm to 600 µm

- Winding wire material: Wide range of materials

- Laser welding: Various material combinations

- Crimping: Various material combinations

- Shape setting: Conventional and proprietary tools and processes

- Surface finishing: Electropolishing (including patented blue oxide treatment), microblasting, mechanical polishing, passivation

The variety of wire technology we offer allows you to move effortlessly from initial prototype through full-scale production.