WE DELIVER PROTOTYPES WITHIN A FEW DAYS. AND THAT’S A PROMISE

Rapid Response prototyping.

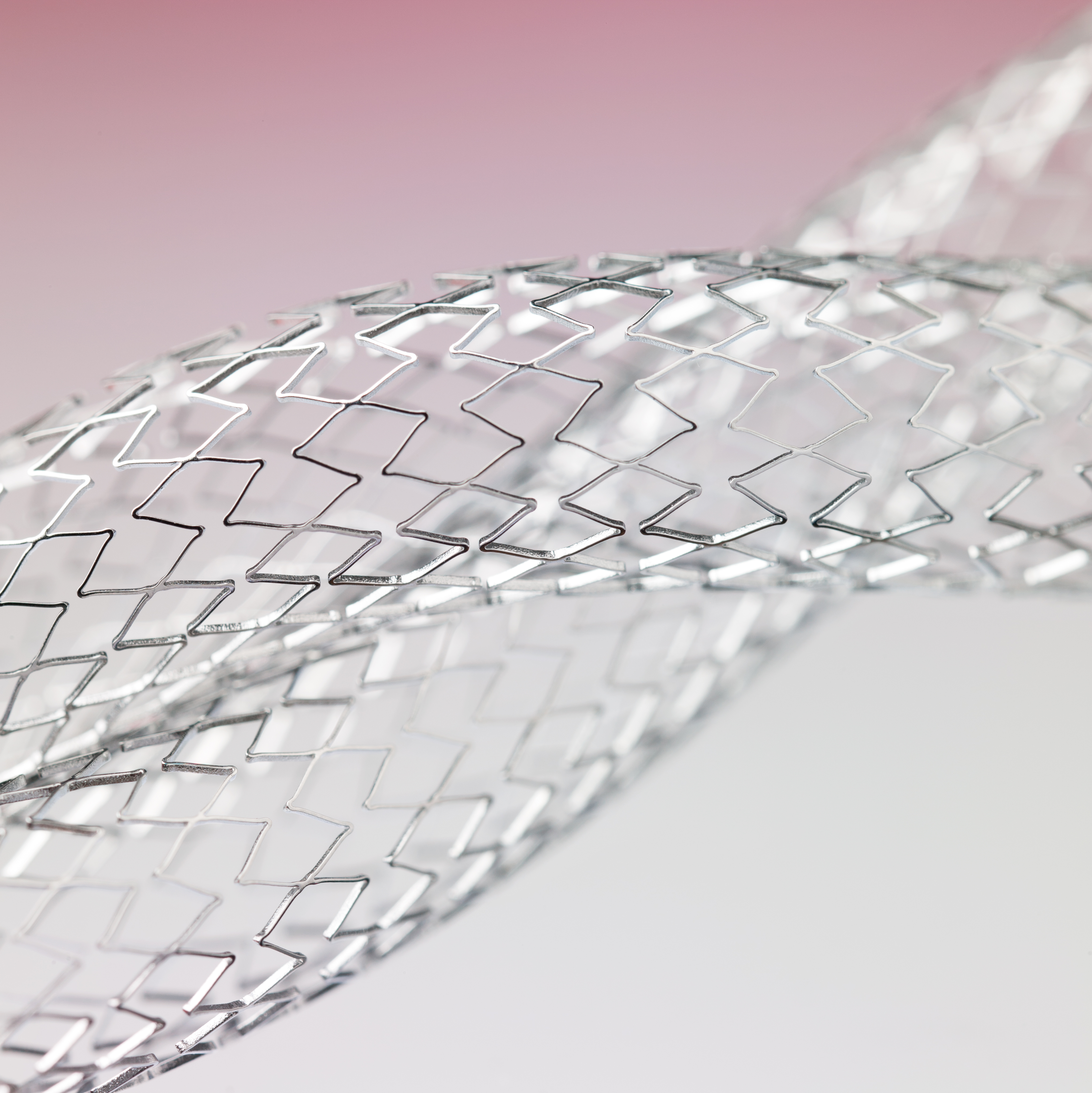

Time equals money when turning an idea into a marketable medical device. To accelerate your journey to profitability, we created a Rapid Response prototyping department staffed with some of our best engineering, material, and technology experts.

To meet our promise to provide prototypes within a few days, we equipped the department with laser cutting, wire technology and microassembly capabilities. Our Rapid Response team works closely with our test lab team and experts throughout the company to deliver top-quality prototypes.

We never sacrifice details for speed.

Instead, we record each step so that you can provide documentation when presenting your idea to internal stakeholders, investors and regulatory agencies.

AT-A-GLANCE FACTS

- Dedicated team of engineers and other experts

- Access to test lab and hundreds of ADMEDES engineers and scientists

- Ultrafast (femtosecond & picosecond) excimer, DPSS and CO2 lasers

- Laser micromanufacturing capabilities: Ablating, cutting, profiling and drilling

- Wire braiding, winding and shape setting

- Capability to handle various geometries: flat sheet, tubular, alternate profiles, and wire

- Surface finishing

Whether you bring a sketch drawn on a napkin or a sophisticated 3-D engineering model, we move with you through development to arrive at a prototype design that delivers what you want with optimized manufacturability.

Explore our other areas of expertise