The depth and breadth of experience we bring to laser cutting can be your competitive advantage.

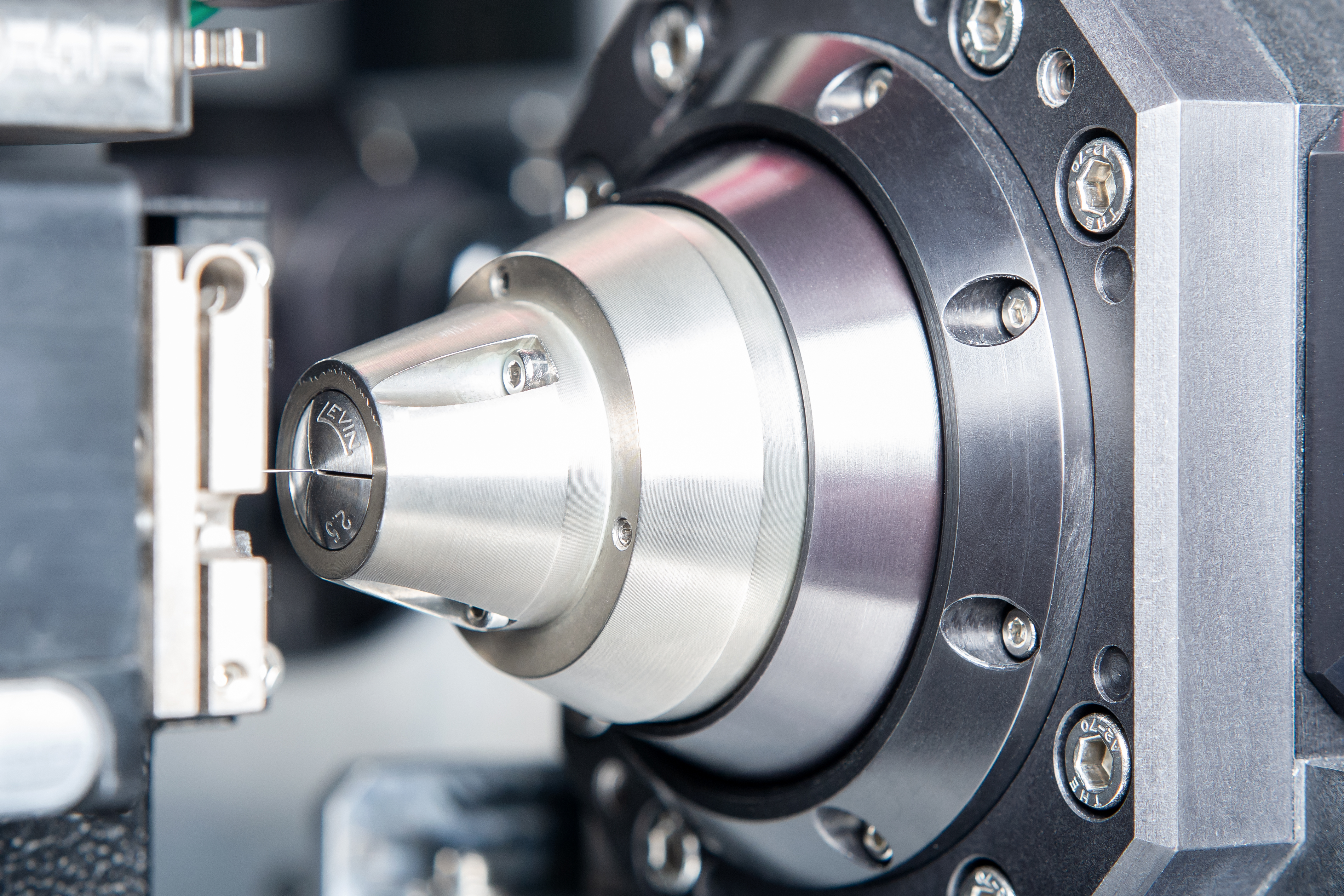

Laser Technology.

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996. We were among the first to use lasers to fabricate nitinol medical device components and continue to be the industry’s laser technology leader.

Our array of fiber-pulsed and ultrashort-pulsed lasers allows us to cut complex geometries for devices ranging from large, rigid heart valve frames to highly flexible and fragile neuro devices. Our skill, capacity and range of laser technology shorten your time to market by enabling us to select the best technology and create and refine prototypes with surprising speed.

We have developed a number of processes that enhance precision and extend the horizon of possibilities. If you feel your idea reaches beyond what is currently achievable in the industry, contact us. We welcome the opportunity to take on your challenge.

AT-A-GLANCE FACTS

- Lasers: Fiber, ultra-short pulse, Nd:YAG

- Laser welding: Various material combinations

- Surface finishing: Electropolishing, patented blue oxide treatment, microblasting, chemical etching and polishing, mechanical polishing, passivation

- Materials: Wide range of materials

- Material formats: Tube, sheet, strip, foil, wire, rods

- Tubing outer diameter: 0.2 mm to 40 mm

- Tubing wall thickness: 20 ųm to 1 mm

- Minimum kerf width: 5 ųm

- Minimum possible strut width: < 25 ųm

We have developed a number of processes that enhance precision and extend the horizon of possibilities. If you feel your idea reaches beyond what is currently achievable in the industry, contact us. We welcome the opportunity to take on your challenge.

Explore our other areas of expertise

- Rapid Response Prototyping

- Wire Technology

- Microassembly

- Simulation & Test Lab Services

- Coating Technology

- NSX Services